Turbojet

A turbojet engine is a gas turbine engine that works by compressing air with an inlet and a compressor (axial, centrifugal, or both), mixing fuel with the compressed air, burning the mixture in the combustor, and then passing the hot, high pressure air through a turbine and a nozzle. The compressor is powered by the turbine, which extracts energy from the expanding gas passing through it. The engine converts internal energy in the fuel to kinetic energy in the exhaust, producing thrust. All the air ingested by the inlet is passed through the compressor, combustor, and turbine, unlike the turbofan engine described below.

A turbojet engine is a gas turbine engine that works by compressing air with an inlet and a compressor (axial, centrifugal, or both), mixing fuel with the compressed air, burning the mixture in the combustor, and then passing the hot, high pressure air through a turbine and a nozzle. The compressor is powered by the turbine, which extracts energy from the expanding gas passing through it. The engine converts internal energy in the fuel to kinetic energy in the exhaust, producing thrust. All the air ingested by the inlet is passed through the compressor, combustor, and turbine, unlike the turbofan engine described below.Turbofan

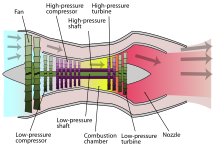

Turbofans differ from turbojets in that they have an additional fan at the front of the engine, which accelerates air in a duct bypassing the core gas turbine engine. Compared to a tubojet of identical thrust, a turbofan has a much larger air mass flow rate. Turbofans are the dominant engine type for medium and long-range airliners

Turbofans differ from turbojets in that they have an additional fan at the front of the engine, which accelerates air in a duct bypassing the core gas turbine engine. Compared to a tubojet of identical thrust, a turbofan has a much larger air mass flow rate. Turbofans are the dominant engine type for medium and long-range airliners.

The comparatively large frontal fan has several effects. The main effect is that the output of the engine as a whole has a much higher mass per second, and therefore generates much more thrust, despite not having ignited much of its airflow. Also, because the additional air has not been ignited, no extra fuel is needed to provide this thrust. The slower average velocity of the mixed exhaust air (low specific thrust) is also less wasteful of energy for subsonic flight, and allows the engine to be more efficient and much quieter, while the fan also allows greater thrust to be available at slow speeds. Together, the thrust produced by the fan and core are much more fuel efficient, and provides a much higher output, than could be produced by the core alone.

Turbofans are usually more efficient than turbojets at subsonic speeds, but their large frontal area also generates more drag;Therefore in supersonic flight, and in military and other aircraft where absolute performance, weight, and drag have a higher priority than fuel efficiency, engines tend to be either have smaller fans (or multiple smaller fans) or use other engine designs entirely. Typically, turbofans in civilian aircraft usually have a pronounced large front area to accommodate a very large fan, as their design involves a much larger mass of air bypassing the core so they can benefit from these effects, while in military aircraft, where noise and efficiency are less important compared to performance and drag, a smaller amount of air typically bypasses the core. Turbofans designed for subsonic civilian aircraft also usually have a just a single front fan, because their additional thrust is generated by a large additional mass of air which is only moderately compressed, rather than a smaller amount of air which is greatly compressed.

Because of these distinctions, turbofan engine designs are often categorized as low-bypass or high-bypass, depending upon the amount of air which bypasses the core of the engine. Low-bypass turbofans have a bypass ratio of around 2:1 or less, meaning that for each kilogram of air that passes through the core of the engine, two kilograms or less of air bypass the core.Low-bypass turbofans often use a mixed exhaust nozzle meaning that the bypassed flow and the core flow exit from the same nozzle.High-bypass turbofans often have ratios from 4:1 up to 8:1, with the Rolls-Royce Trent XWB approaching 10:1.

Turboprop and turboshaft

Turboprop engines are jet engine derivatives, still gas turbines, that extract work from the hot-exhaust jet to turn a rotating shaft, which is then used to produce thrust by some other means. While not strictly jet engines in that they rely on an auxiliary mechanism to produce thrust, turboprops are very similar to other turbine-based jet engines, and are often described as such.

Turboprop engines are jet engine derivatives, still gas turbines, that extract work from the hot-exhaust jet to turn a rotating shaft, which is then used to produce thrust by some other means. While not strictly jet engines in that they rely on an auxiliary mechanism to produce thrust, turboprops are very similar to other turbine-based jet engines, and are often described as such.In turboprop engines, a portion of the engine's thrust is produced by spinning a propeller, rather than relying solely on high-speed jet exhaust. As their jet thrust is augmented by a propeller, turboprops are occasionally referred to as a type of hybrid jet engine. They are quite similar to turbofans in many respects, except that they use a traditional propeller to provide the majority of thrust, rather than a ducted fan. Both fans and propellers are powered the same way, although most turboprops use gear-reduction between the turbine and the propeller (geared turbofans also feature gear reduction). While many turboprops generate the majority of their thrust with the propeller, the hot-jet exhaust is an important design point, and maximum thrust is obtained by matching thrust contributions of the propeller to the hot jet.Turboprops generally have better performance than turbojets or turbofans at low speeds where propeller efficiency is high, but become increasingly noisy and inefficient at high speeds.

Turboshaft engines are very similar to turboprops, differing in that nearly all energy in the exhaust is extracted to spin the rotating shaft, which is used to power machinery rather than a propeller, they therefore generate little to no jet thrust and are often used to power helicopters.

Propfan

A propfan engine (also called "unducted fan", "open rotor", or "ultra-high bypass") is a jet engine that uses its gas generator to power an exposed fan, similar to turboprop engines. Like turboprop engines, propfans generate most of their thrust from the propeller and not the exhaust jet. The primary difference between turboprop and propfan design is that the propeller blades on a propfan are highly swept to allow them to operate at speeds around Mach 0.8, which is competitive with modern commercial turbofans. These engines have the fuel efficiency advantages of turboprops with the performance capability of commercial turbofans.While significant research and testing (including flight testing) has been conducted on propfans, no propfan engines have entered production.

A propfan engine (also called "unducted fan", "open rotor", or "ultra-high bypass") is a jet engine that uses its gas generator to power an exposed fan, similar to turboprop engines. Like turboprop engines, propfans generate most of their thrust from the propeller and not the exhaust jet. The primary difference between turboprop and propfan design is that the propeller blades on a propfan are highly swept to allow them to operate at speeds around Mach 0.8, which is competitive with modern commercial turbofans. These engines have the fuel efficiency advantages of turboprops with the performance capability of commercial turbofans.While significant research and testing (including flight testing) has been conducted on propfans, no propfan engines have entered production.Ram powered

Ram powered jet engines are airbreathing engines similar to gas turbine engines and they both follow the Brayton cycle. Gas turbine and ram powered engines differ, however, in how they compress the incoming airflow. Whereas gas turbine engines use axial or centrifugal compressors to compress incoming air, ram engines rely only on air compressed through the inlet or diffuser.Ram powered engines are considered the most simple type of air breathing jet engine because they can contain no moving parts.Ramjet

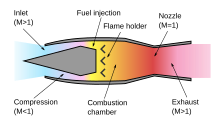

Ramjets are the most basic type of ram powered jet engines. They consist of three sections; an inlet to compress incoming air, a combustor to inject and combust fuel, and a nozzle to expel the hot gases and produce thrust. Ramjets require a relatively high speed to efficiently compress the incoming air, so ramjets cannot operate at a standstill and they are most efficient at supersonic speeds. A key trait of ramjet engines is that combustion is done at subsonic speeds. The supersonic incoming air is dramatically slowed through the inlet, where it is then combusted at the much slower, subsonic, speeds. The faster the incoming air is, however, the less efficient it becomes to slow it to subsonic speeds. Therefore, ramjet engines are limited to approximately Mach 5.

Ramjets are the most basic type of ram powered jet engines. They consist of three sections; an inlet to compress incoming air, a combustor to inject and combust fuel, and a nozzle to expel the hot gases and produce thrust. Ramjets require a relatively high speed to efficiently compress the incoming air, so ramjets cannot operate at a standstill and they are most efficient at supersonic speeds. A key trait of ramjet engines is that combustion is done at subsonic speeds. The supersonic incoming air is dramatically slowed through the inlet, where it is then combusted at the much slower, subsonic, speeds. The faster the incoming air is, however, the less efficient it becomes to slow it to subsonic speeds. Therefore, ramjet engines are limited to approximately Mach 5.Scramjet

Scramjets are mechanically very similar to ramjets. Like a ramjet, they consist of an inlet, a combustor, and a nozzle. The primary difference between ramjets and scramjets is that scramjets do not slow the oncoming airflow to subsonic speeds for combustion, they use supersonic combustion instead. The name "scramjet" comes from "Supersonic Combusting Ramjet." Since scramjets use supersonic combustion they can operate at speeds above Mach 6 where traditional ramjets are too inefficient. Another difference between ramjets and scramjets comes from how each type of engine compresses the oncoming airflow: while the inlet provides most of the compression for ramjets, the high speeds at which scramjets operate allow them to take advantage of the compression generated by shock waves, primarily oblique shocks.

Scramjets are mechanically very similar to ramjets. Like a ramjet, they consist of an inlet, a combustor, and a nozzle. The primary difference between ramjets and scramjets is that scramjets do not slow the oncoming airflow to subsonic speeds for combustion, they use supersonic combustion instead. The name "scramjet" comes from "Supersonic Combusting Ramjet." Since scramjets use supersonic combustion they can operate at speeds above Mach 6 where traditional ramjets are too inefficient. Another difference between ramjets and scramjets comes from how each type of engine compresses the oncoming airflow: while the inlet provides most of the compression for ramjets, the high speeds at which scramjets operate allow them to take advantage of the compression generated by shock waves, primarily oblique shocks. Very few scramjet engines have ever been built and flown. In May 2010 the Boeing X-51 set the endurance record for the longest scramjet burn at over 200 seconds.

Non-continuous combustion

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Motorjet | Obsolete type that worked like a turbojet but instead of a turbine driving the compressor a piston engine drives it. | Higher exhaust velocity than a propeller, offering better thrust at high speed | Heavy, inefficient and underpowered. Example: Caproni Campini N.1. |

| Pulsejet | Air is compressed and combusted intermittently instead of continuously. Some designs use valves. | Very simple design, commonly used on model aircraft | Noisy, inefficient (low compression ratio), works poorly on a large scale, valves on valved designs wear out quickly |

| Pulse detonation engine | Similar to a pulsejet, but combustion occurs as a detonation instead of a deflagration, may or may not need valves | Maximum theoretical engine efficiency | Extremely noisy, parts subject to extreme mechanical fatigue, hard to start detonation, not practical for current use |

Rocket

The rocket engine uses the same basic physical principles as the jet engine for propulsion via thrust, but is distinct in that it does not require atmospheric air to provide oxygen; the rocket carries all components of the reaction mass. This allows them to operate at arbitrary altitudes and in space.

The rocket engine uses the same basic physical principles as the jet engine for propulsion via thrust, but is distinct in that it does not require atmospheric air to provide oxygen; the rocket carries all components of the reaction mass. This allows them to operate at arbitrary altitudes and in space.This type of engine is used for launching satellites, space exploration and manned access, and permitted landing on the moon in 1969.

Rocket engines are used for high altitude flights, or anywhere where very high accelerations are needed since rocket engines themselves have a very high thrust-to-weight ratio.

However, the high exhaust speed and the heavier, oxidizer-rich propellant results in far more propellant use than turbofans. Even so, at extremely high speeds they become energy-efficient.

An approximate equation for the net thrust of a rocket engine is:

is the net thrust,

is the net thrust,  is the specific impulse,

is the specific impulse,  is a standard gravity,

is a standard gravity,  is the propellant flow in kg/s,

is the propellant flow in kg/s,  is the cross-sectional area at the exit of the exhaust nozzle, and

is the cross-sectional area at the exit of the exhaust nozzle, and  is the atmospheric pressure.

is the atmospheric pressure.| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Rocket | Carries all propellants and oxidants on board, emits jet for propulsion | Very few moving parts. Mach 0 to Mach 25+; efficient at very high speed (> Mach 5.0 or so). Thrust/weight ratio over 100. No complex air inlet. High compression ratio. Very high-speed (hypersonic) exhaust. Good cost/thrust ratio. Fairly easy to test. Works in a vacuum; indeed, works best outside the atmosphere, which is kinder on vehicle structure at high speed. Fairly small surface area to keep cool, and no turbine in hot exhaust stream. Very high-temperature combustion and high expansion-ratio nozzle gives very high efficiency, at very high speeds. | Needs lots of propellant. Very low specific impulse—typically 100–450 seconds. Extreme thermal stresses of combustion chamber can make reuse harder. Typically requires carrying oxidizer on-board which increases risks. Extraordinarily noisy. |

Hybrid

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Turborocket | A turbojet where an additional oxidizer such as oxygen is added to the airstream to increase maximum altitude | Very close to existing designs, operates in very high altitude, wide range of altitude and airspeed | Airspeed limited to same range as turbojet engine, carrying oxidizer like LOX can be dangerous. Much heavier than simple rockets. |

| Air-augmented rocket | Essentially a ramjet where intake air is compressed and burnt with the exhaust from a rocket | Mach 0 to Mach 4.5+ (can also run exoatmospheric), good efficiency at Mach 2 to 4 | Similar efficiency to rockets at low speed or exoatmospheric, inlet difficulties, a relatively undeveloped and unexplored type, cooling difficulties, very noisy, thrust/weight ratio is similar to ramjets. |

| Precooled jets / LACE | Intake air is chilled to very low temperatures at inlet in a heat exchanger before passing through a ramjet and/or turbojet and/or rocket engine. | Easily tested on ground. Very high thrust/weight ratios are possible (~14) together with good fuel efficiency over a wide range of airspeeds, Mach 0-5.5+; this combination of efficiencies may permit launching to orbit, single stage, or very rapid, very long distance intercontinental travel. | Exists only at the lab prototyping stage. Examples include RB545, Reaction Engines SABRE, ATREX. Requires liquid hydrogen fuel which has very low density and requires heavily insulated tankage. |

Water jet

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Water jet | For propelling water rockets and jetboats; squirts water out the back through a nozzle | In boats, can run in shallow water, high acceleration, no risk of engine overload (unlike propellers), less noise and vibration, highly maneuverable at all boat speeds, high speed efficiency, less vulnerable to damage from debris, very reliable, more load flexibility, less harmful to wildlife | Can be less efficient than a propeller at low speed, more expensive, higher weight in boat due to entrained water, will not perform well if boat is heavier than the jet is sized for |

No comments:

Post a Comment